Backingless less cold laminating films eliminate paper backing waste, offering eco-friendly adhesion for signage and graphics. Unlike traditional cold laminating films requiring liner removal, this innovative solution reduces material costs by 30% and speeds application processes. Both options protect surfaces from scratches/UV damage, but linerless films excel in high-volume printing environments through seamless automation compatibility. Traditional cold laminating films remain ideal for small-scale DIY projects with precise positioning needs. Choose linerless for sustainable, large-format commercial applications or traditional films for detailed craft projects. Certified for archival-grade protection (ISO 18916), our films maintain color vibrancy for 5+ years outdoor exposure.

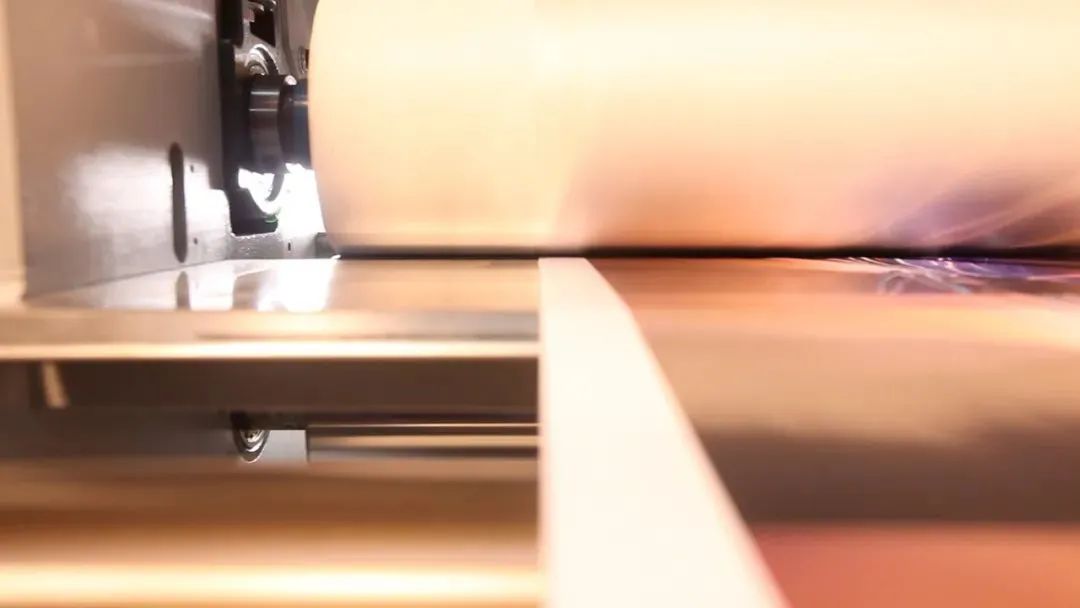

1、Bottomless paper cold laminating film

Cold laminating film is a kind of protective film, handmade or with cold laminating machine mounted on the picture of the photographic printing,

to avoid the picture (printing surface) is scratched, polluted or wet,

play a role in protecting the picture. It is widely used in wedding photos, oil painting, calligraphy and painting, outdoor posters, advertisements, all kinds of pictures, documents, information and so on.

2、Features of backing paperless cold laminating film\

Adhesive performance using new fabrics and high-definition glue refined by German technology, with strong ductility and adhesive effect!

Affordable price eliminates backing paper, cost reduction, more affordable!

Laminating speed fast laminating speed, up to more than 20 meters per minute, several times faster than the traditional film, significantly improving the advertising production company’s ability to deliver orders!

Automatic laminating only one machine can complete the laminating and cutting, greatly saving labor costs!

Good laminating effect color reproduction up to 95% or more! No wrinkles! No shrinkage of edges! Excellent picture framing effect!

3、Bottomless paper cold laminating film classification

Bottomless paper cold laminating film according to the texture of the film surface can be divided into light film, frosted film (matte film).

Light film light film surface flat and bright, high transparency, moisture-proof, anti-corrosion, good durability, easy to clean, easy to install, light weight, non-flammable.

Frosted film (matte film) frosted film surface are frosted texture, the advantages of effective resistance to fingerprints, easy to clean. There is a slight effect on the display effect, unique feel, giving the picture effect grade enhancement.

4、Application of backing paperless cold laminating film

Cold laminating film is made of transparent PVC through the backing process, according to the texture of the film surface can be divided into light film, matte film, frosted film, star phantom film,

laser film and special texture of the protective film, a large number of advertisements used in the production of light film, matte film, frosted film. Cold laminating film is used by hand or cold

laminating machine etc. to laminate on the picture printed on the screen to avoid the picture (printing surface) being scratched, polluted or wet, and play the role of protecting the picture.

JinGe Technology

Jiangxi Jinge Technology Co.

Search within the site

© 2026. All Rights Reserved.