Transform banners, posters, & retail displays with cold laminating film—the go-to for advertising consumables! 🌎 This guide teaches pros how to apply it to PVC, paper, or fabric: waterproof outdoor banners, scratch-resistant store signage, or vibrant trade show graphics. No heat, no wrinkles—perfect for delicate substrates. Discover 5 pro hacks: layer for UV protection, use matte finish for anti-glare, or glossy for premium look. Why advertisers love it: 3x longer lifespan than unlaminated prints. Includes step-by-step for beginners + pro tips for scaling production. Cold laminating film keeps ads vibrant in rain, sun, or humidity—ideal for agencies, printers, & small businesses. SEO-optimized for “advertising consumables guide” & “cold laminating film tips”—elevate campaigns today!

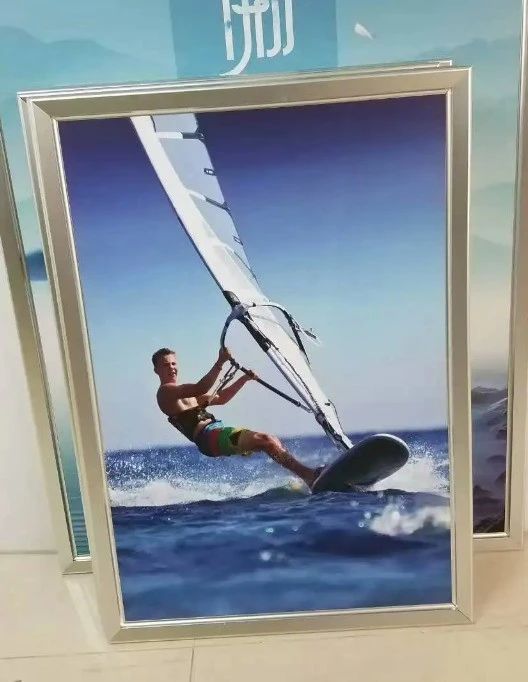

1. Specialized display board for cold lamination

Adopting polystyrene core layer + cold laminating special laminating process, the board surface is flat and bubble-free, supporting UV cold laminating printing, suitable for promotional display boards, conference backboards and other scenes, weather resistance is 3 times higher than traditional KT boards.

2、Cold laminating and spraying substrate

Upgraded PVC cold laminating coating technology, knife scraping cloth/calendering cloth surface by cold laminating film treatment, UV resistance index of 8, applicable to outdoor high-precision car stickers, building enclosure advertising, to solve the problem of fading of traditional spray painting.

3、Cold laminating light box film

Specializing in semi-transparent cold laminating composite technology, to achieve double-sided visual effect (light transmission rate of 65% ± 5), with LED light source service life of 50,000 hours, has gradually replaced the traditional film light box sheet.

4、Cold laminating synthetic paper

Environmentally friendly PP synthetic paper (thickness 0.15-0.3mm) with low-temperature cold laminating adhesive layer, suitable for X-racks, easy-open and other temporary exhibition tools, 5 minutes fast laminating without warping, indoor preservation cycle extended to 2 years.

5、Cold laminating banner cloth

Innovative cold laminating coating process makes the banner fabric wash-resistant more than 20 times, with Latex environmental protection ink, outdoor use cycle up to 18 months, the cost is 40% lower than the traditional process.

6、Cold lamination filmcar stickers

Three-layer composite structure (PET release layer + cold laminating adhesive layer + color printing layer), support for 3M dynamic lamination technology, scratch-resistant grade up to 9H, dedicated to the field of public transportation advertising.

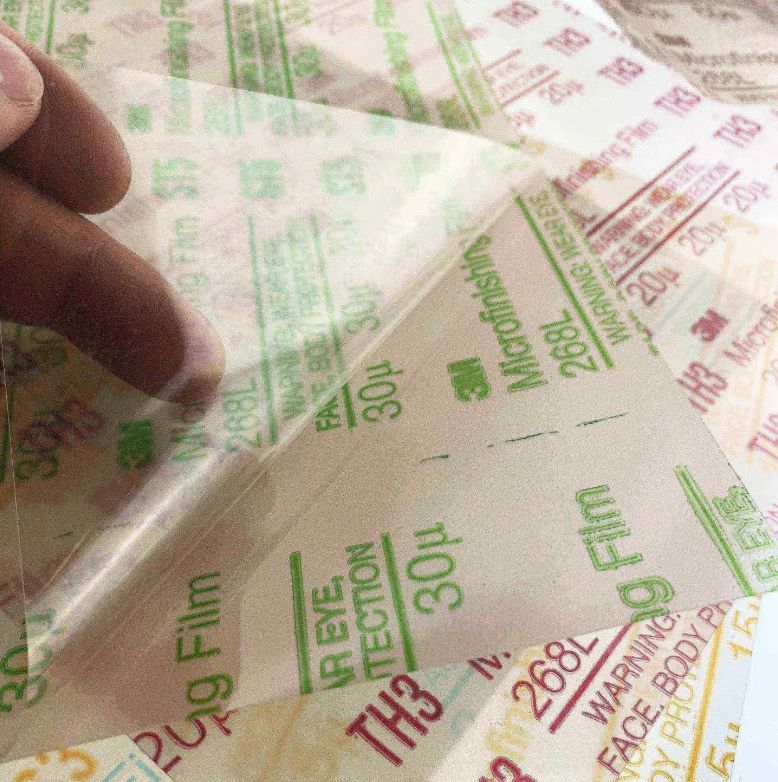

7、Cold laminating transparent film

0.25mm optical grade transparent cold laminating film (light transmittance 92%), support for laser engraving shaped laminating film, used in window UV protection laminating film, can reduce the indoor temperature by 3-5℃.

8、Cold laminating instant stickers

Cold laminating special removable adhesive (residual value ≤ 0.5%), suitable for acrylic board/glass/metal and other substrates, 72 hours without trace removal, reuse rate of more than 5 times.

9、 cold laminating one-way see-through film

Black and white double-sided cold laminating composite process (shading rate of 99.8%), to solve the traditional single-hole pass easy to decouple the problem, suitable for banks / shopping malls privacy protection and advertising integration solutions.

JinGe Technology

Jiangxi Jinge Technology Co.

Search within the site

© 2026. All Rights Reserved.