Transform banners, posters, & signs with cold laminating film—ideal for advertising materials! Protect prints from UV, rain, & scratches while boosting gloss/matte finishes. Learn why pros choose this no-heat solution for billboards, retail displays, & trade show graphics. The master’s guide reveals application hacks, cost-saving tricks, & why cold laminating film outlasts traditional laminates in advertising. Perfect for designers, printers, & marketers—get 16 years of insights to elevate campaigns!

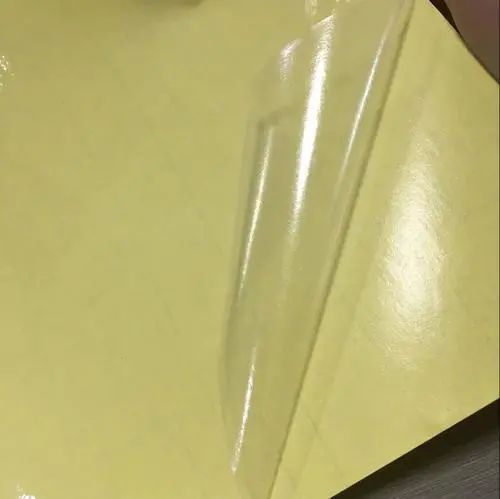

Cold laminating film is made of transparent PVC through the backing process, according to the texture of the film surface can be divided into light film, matte film, frosted film, star phantom film, laser film and special texture of the protective film, in the production of advertising a large number of use is light film, matte film, frosted film. Cold laminating film is used by hand or cold laminating machine etc. to laminate on the screen of photo printing, to avoid the screen (printing surface) from being scratched, polluted or drenched, and to play the role of protecting the screen.

Cold laminating film can increase the texture of the picture, and protect the picture, scratch-resistant and water-resistant. But it can not make the photo image has a high degree of anticorrosive and anti-ultraviolet erosion, ultraviolet rays will penetrate the cold laminating film to make the picture fade, and after a long time, the cold laminating film will be brittle. It can be widely used in wedding photo, oil painting production, calligraphy and painting, outdoor posters, advertisements, all kinds of pictures, documents, information …… and so on. Now we can provide more than twenty models, various patterns, glossy/matt surface and laser series and other products. Applied to larger advertising, architectural decorative effects, background decoration, etc., the use of cold laminating film web protection effect is better at present the largest amount of advertising is the light film and matte film.

In the mounting of more than 1.5 meters of the figure, the main thing is to prevent the figure and the film skewed. Just pressed into the part of the shaft is not a hair’s breadth, but after a length of time will be a thousand miles. So the operation method must be appropriate. The production of ultra-long picture first of all to the upper shaft lift to the maximum degree of lifting, and secondly, the cold laminating film and figure overlap together, cold laminating film in the upper, figure in the lower (cold laminating film adhesive surface in the upper, figure the front side of the isolation of the paper close to the back of the roll into a cylinder, put one end on the clean ground, or tabletop poking, pinch with your hand, do not let the film wrongly placed, will be the cold laminating film and the figure into the same time between the two shafts.

At this time, there is a need for a person in the back of the machine to catch the picture and cold laminating film sent over in front, to prevent loose misplaced, try to put on the machine, hold flat, and then move the upper axis parallel downward, the pressure is adjusted (according to the adjustment method mentioned earlier) to press the cold laminating film and the picture. In order to ensure that the picture being mounted with the film does not produce skew, you can first turn the machine, try to go through, but do not go out of the axis. If found during the test walk skewed, should be re-opened. If not skewed, you can stop the rotation in any position, the end of the cold laminating film lifted up. Use scissors to cut the isolation paper (pay attention not to cut the film), and then turned outward to the other side, turn the machine, in the shaft rotation at the same time, constantly to isolate the paper uncovered down, the film was mounted on the map, the above part is completed, and then reverse the rotation of the machine with the same method will be the other side of the map is also mounted on the film to this laminating work is fully completed. Buy wide material, look for Glory!

JinGe Technology

Jiangxi Jinge Technology Co.

Search within the site

© 2026. All Rights Reserved.