1、Things to Know Before Using Cold Laminating Film

In the cold laminating film information , the characteristics and application scope of cold laminating film receive much attention. Cold laminating film is highly flexible, allowing it to easily conform to objects of various shapes. It also has excellent waterproof and dustproof properties, making it useful for a wide range of applications, such as laminating photos and posters. This is an important part of the Cold Laminating Film Solutions. Before using cold laminating film, it is crucial to clean the item to be laminated. For instance, when laminating a photo, you should use a clean soft cloth to wipe off the dust and stains on the photo’s surface, ensuring it is spotless. This is also a necessary preparatory step that cannot be overlooked in the Cold Laminating Film Solutions. Only in this way can the cold laminating film adhere better and give full play to its advantages. This is also a key point of the Cold Laminating Film Solutions, resulting in an excellent laminating effect.

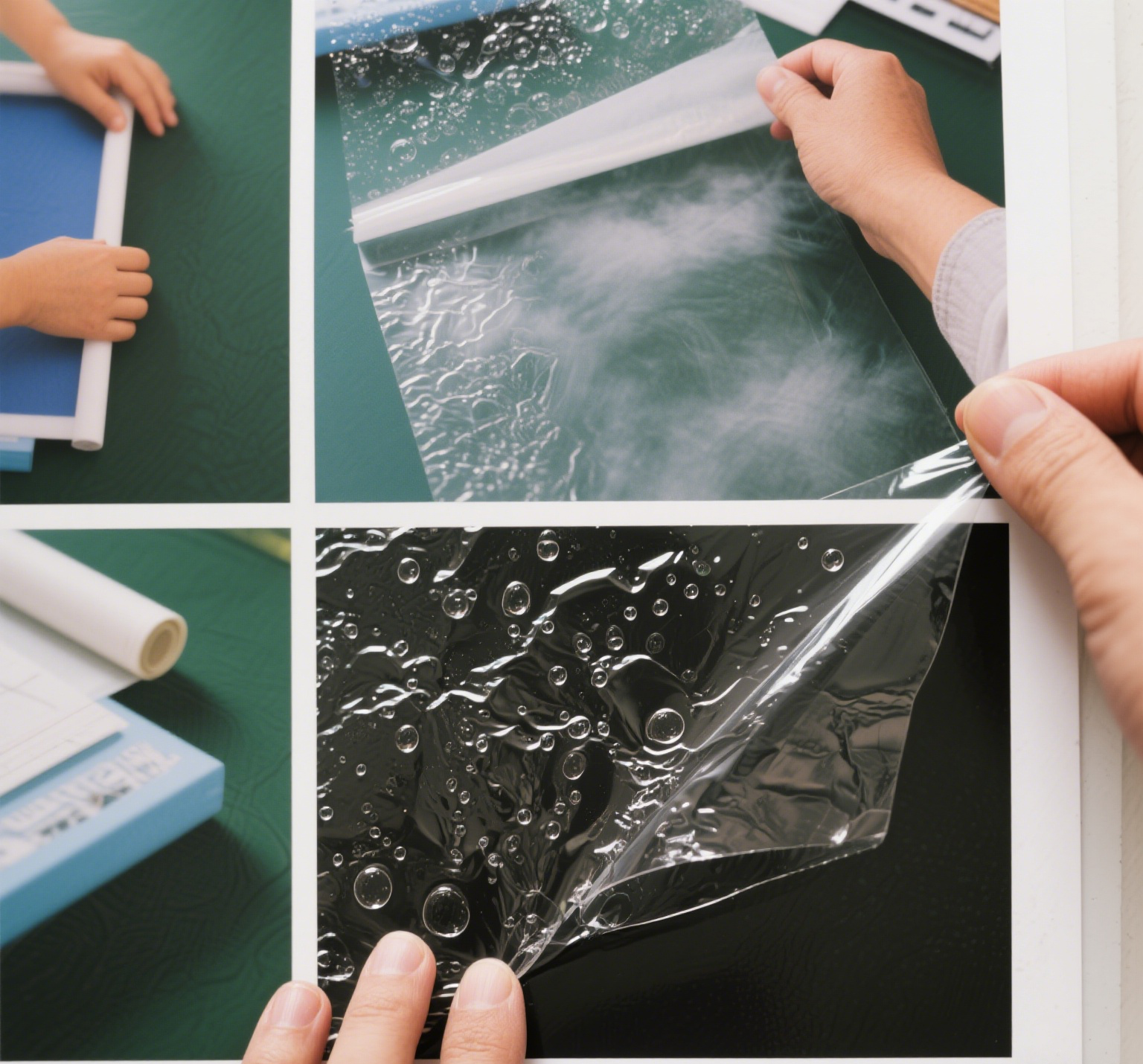

2、Solving the Blistering Problem

When using cold laminating films like laser cold laminating film and light film cold laminating film, the blistering phenomenon and its impact on the lamination effect must be taken seriously. The blistering phenomenon and its impact on the lamination effect are quite obvious. Once the film blisters, the surface becomes uneven, and the originally shiny and laser-effect areas turn patchy, severely spoiling the appearance. If a photo is laminated with laser cold laminating film and blisters occur, the photo will look blurred and cannot be properly displayed.

Don’t worry. Here comes the Cold Laminating Film Solutions. When applying the film, slowly stick it from one end to the other while using a squeegee to gently scrape and push the air out to the sides. This is a key technique in the Cold Laminating Film Solutions to avoid blistering. As long as you follow this method, you can solve the blistering problem. This is also an important part of the Cold Laminating Film Solutions, enabling the laser cold laminating film and glossy film to adhere perfectly and present an excellent lamination effect.

3、Overcoming the Fogging Troubles

When using cold laminating films such as shattered glass cold laminating film or frosted cold laminating film, the fogging state and its hazards should not be ignored. Once fogging occurs, the film surface will become blurry, as if covered with a layer of fog, and the originally clear patterns or texts will turn hazy. This is a typical fogging state and its hazards, which greatly reduce the lamination effect and make it lose its original beauty and clarity. If a painting is laminated with broken glass cold laminating film and fogging occurs, the details of the painting will not be clearly visible.

Don’t worry. The Cold Laminating Film Solutions has a way out. Before pasting, make sure both the item to be laminated and the cold laminating film are dry and clean. This is the basis for preventing fogging in the Cold Laminating Film Solutions. Also, the environmental humidity should not be too high during pasting, and you should follow the standard operation procedures. By following such a Cold Laminating Film Solutions, you can effectively eliminate fogging, allowing the broken glass cold laminating film and frosted cold laminating film to show their proper effects and no longer be troubled by fogging.

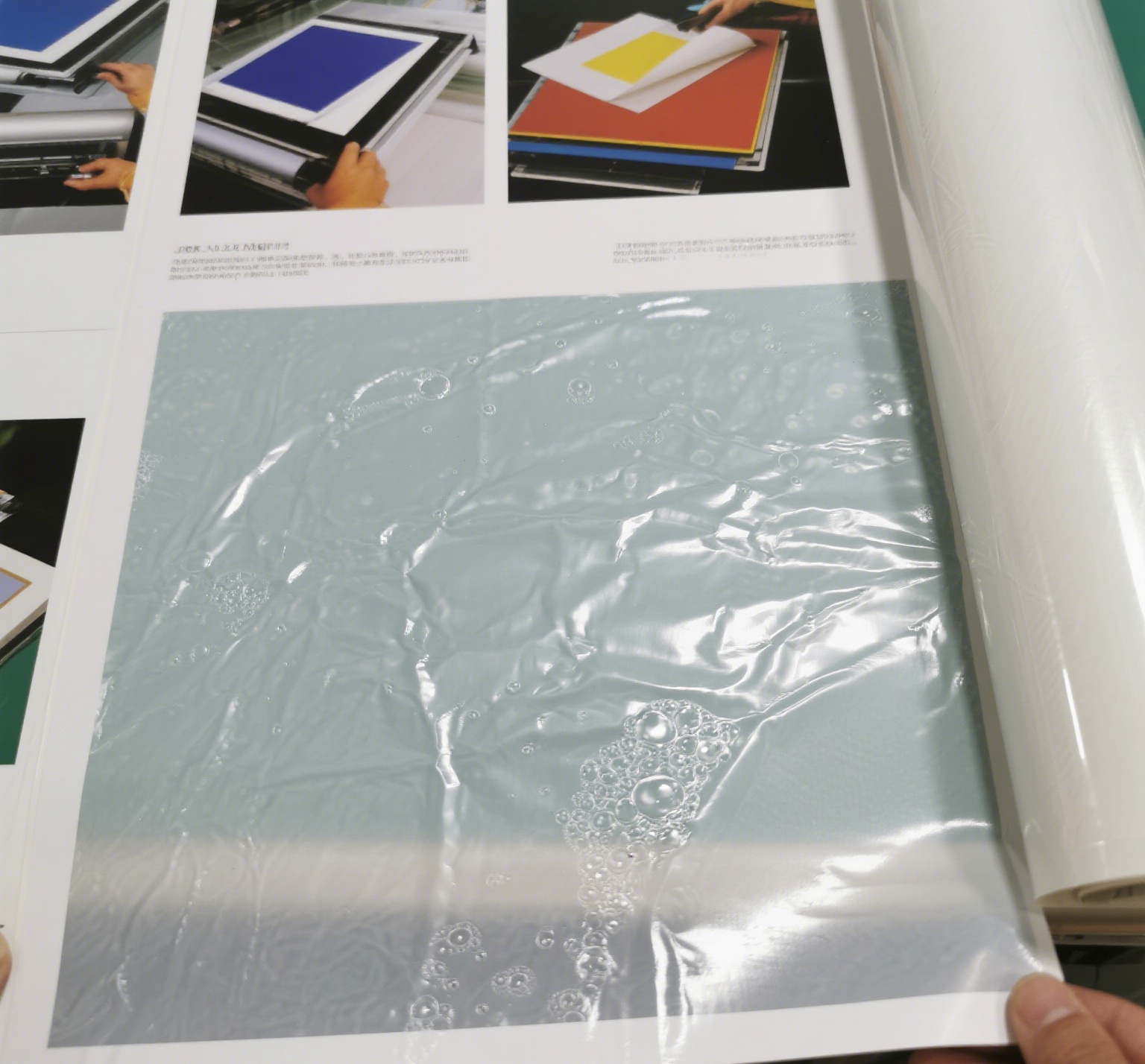

4、Resolving the Wrinkling Dilemma

When using cold laminating films like fine sand star cold laminating film and flash point cold laminating film, the manifestations and consequences of wrinkling need to be paid special attention to. The manifestations and consequences of wrinkling are very obvious. When wrinkling occurs, there will be streaks of wrinkles on the film surface, just like crumpled paper. This not only spoils the originally shiny effect of the cold laminating film. For example, the distribution of stars on the fine star cold laminating film becomes uneven, and the flash points of the flash point cold laminating film cannot shine normally, seriously affecting the appearance. This is the manifestations and consequences of wrinkling. Moreover, dirt and dust are likely to accumulate in the wrinkled areas, shortening the service life of the laminated item.

Don’t panic. The Cold Laminating Film Solutions can help you. Before pasting the cold laminating film, carefully flatten the item to be laminated to ensure there are no wrinkles. This is a crucial step in the Cold Laminating Film Solutions. When pasting, move gently and slowly, push the film evenly from one end to the other, and use a squeegee to make the film adhere closely to the item. By following such a Cold Laminating Film Solutions, you can effectively avoid wrinkling, enable the cold laminating film to perform at its best, and extend the service life of the laminated item.

5、Improving Usage Skills and Summary

Jingge Technology provides us with a wealth of practical cold laminating film knowledge . When using cold laminating film, mastering the operation skills is crucial for avoiding various problems in the long run. This is also the key to the Cold Laminating Film Solutions. For example, before pasting, make sure the surface of the item to be laminated is clean and flat. This is a basic skill and an important part of the Cold Laminating Film Solutions. When pasting, slowly stick the film from one side to the other while using a squeegee to gently scrape and expel the air. This can prevent problems like blistering and is also a key point of the Cold Laminating Film Solutions. Jingge Technology reminds you that as long as you continuously follow these operation skills, such as paying attention to environmental humidity and temperature, you can stay away from troubles like blistering, wrinkling, and fogging in the long term, ensuring that the cold laminating film always maintains a good effect. This is the complete Cold Laminating Film Solutions.

JinGe Technology

Jiangxi Jinge Technology Co.

Search within the site

© 2026. All Rights Reserved.